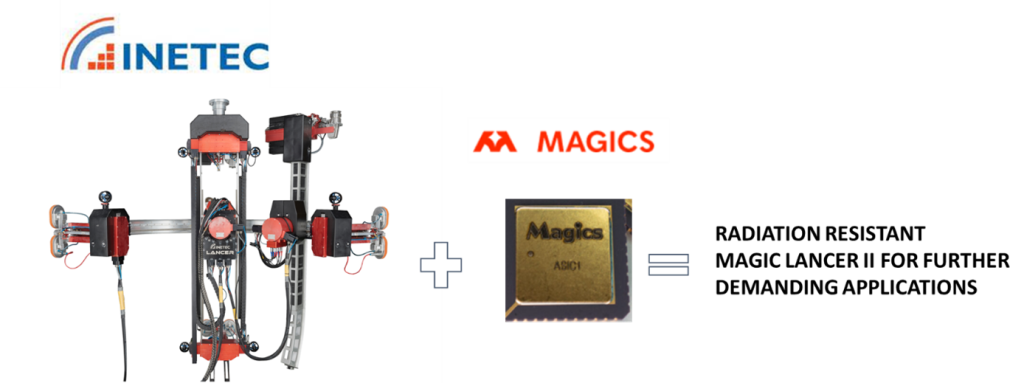

INETEC – Institute for Nuclear Technology is a well-known international engineering company located in Croatia and specialised in robotic systems, instruments, probes and software for nuclear power plant examination, inspection, repair services and R&D studies. In October 2021, INETEC started a project in the scope of the EU-funded RIMA project (Robot recruitment for inspection and maintenance operations) to develop a fully digital and more sustainable radiation-resistant robotic manipulator “LANCER II” to support nuclear inspections at the reactor vessel.

The research included two main parts: the first was about the development of the manipulator that represents a new generation of mobile and light robotic systems developed at INETEC to perform the complete examination of reactor pressure vessel (RPV) shell- UT, ET, VT on both pressurized water (PWR) and VVER (water-water energetic) reactor types.

The manipulator is adaptable to various reactor vessel types and sizes, can perform operations under water and uses vacuum grippers to be in contact with the RPV surface. Thanks to its lightweight, its several degrees of freedom driven by electric motors and propulsion system, the robot is easy to operate and can navigate in complex environments.

ITER related radiation resistant components helps increasing the reliability of the LANCER II and enlarging the scope of NDT inspections in demanding environments

The second part of the project concerned the evaluation of the maximum radiations that the control board of the LANCER II robot can withstand and the development of radiation resistant microchips to evaluate the feasibility of new applications in more demanding environments. On this task, INETEC worked in cooperation with Magics Technologies.

During fusion experiments at ITER, the plasma will generate gamma and neutron ionizing radiations generated by deuterium and tritium reactions. The resulting radiation levels are making maintenance operations hazardous for humans and require the use of remotely operated robotics machinery. Therefore, in order to deliver ITER Remote Handling Systems resistant to ionizing radiations, Fusion For Energy implemented the ICARHE Research and Development program on radiation tolerant electronics. Magics successfully contributed to the ICARHE program by developing and validating a portfolio of novel radiation tolerant electronics. – Laura Mont, Technical Project Officer of the ICARHE Program, Fusion for Energy (F4E)

We believe that the radiation tolerant ASICs developed by Magics represent a breakthrough for cutting-edge robotics applications in the nuclear field beyond the fusion world. – Emilio Ruiz Morales, Project Manager for Remote Handling Control Systems and Radiation Tolerant Technologies, Fusion for Energy (F4E)

Europe’s contribution to ITER offers companies the opportunity to increase their competitiveness and to transfer the know-how of fusion applications to non-fusion ones. – Carmen Casteras, Intellectual Property and Technology Transfer Officer, Fusion for Energy (F4E).

For this reason, Magics developed in collaboration with F4E an innovative radiation resistant ASICs (Application-specific integrated circuits) for position sensing, motion control and bus communication. The circuits consist of five radiation resistant systems on-chip: an angle and position readout system, a relay driver ASIC, a limit switch, a generic conditioning readout system and a communication bus. These components are “Rad-hard-by-Design”, do not require shielding and have been specifically designed to withstand tremendous amount of radiation, larger than 1 MGy total-ionizing-dose. Such a level of performance had never been achieved before. – Luisa Leroy, Business Developer, Magics

The teams at INETEC have re-designed their modular printed circuit and developed a new control board based on Magics’ radiation resistant microchips as possible replacement of the modular non-rad-hard printed circuit board design. The objective here was to benefit from the expected radiation resistance equal to 1 MGy of the accumulated dose that Magics achieved during a previous project with F4E for fusion environment.

Both designs have been tested at VF Nuclear, where ionising radiation monitoring devices are produced. The radiation resistant board did not show any sign of dysfunction after accumulating the dosage equal to 600Gy, while the standard components of the modular printed circuit board ceased to function at different levels of accumulated radiation dose.

This new design based on Magics components opens the opportunity to create lightweight, small and robust end-products and solutions, reduce power consumption during operations and increase the overall lifetime of the devices. It also enables digitalisation in high radiation environments

Thanks to this project, INETEC has gathered relevant data for the selection of electronic components that work in radioactive environments. Moreover, a solution for operations under extreme conditions has also been developed. Thanks to INETEC high-tech expertise in inspection of nuclear reactors and pressure vessels and Magics radiation resistant ASICs, both companies will be striving to solve future nuclear challenges.

A successful collaboration that led to increased know-how and product reliability for INETEC and new business opportunities for the MAGIC’s radhard microchips

Although the test highlighted that certain standard components of the modular printed circuit board did not endure the dosage level, INETEC knows now what the maximum radiation dosage they can receive. Thanks to this project, INETEC has gathered relevant data for the selection of electronic components that work in radioactive environments. All this enabled them to take a step forward in increasing the quality and reliability of INETEC’s products.

The know-how generated from the Magic Lancer II project has unlocked more possibilities to offer technological solutions to more demanding requirements. Development and implementation of the radiation-hardened electronics in our robotics assortment will largely increase the reliability of our systems and enlarge the scope of NDT inspections in the nuclear industry. The project contributes to INETEC’s ability to provide better services to our clients and satisfy more diverse conditions in the ever-changing non-destructive testing industry – Petra Lauš, Senior Marketing Communications Associate at INETEC

On Magics’ side, the collaboration with F4E enabled the fast-growing Belgian SME to address the nuclear robotics market which is expected to reach $157 billion in 2030. As the modular radiation resistant ASICs can be implemented on any nuclear remote device thanks to a plug and play configuration, the company expects to rapidly raise its number of customers in the coming years and targets both nuclear power plants operators and their subcontractors. By contributing to design and build more efficient monitoring systems for nuclear power plants, Magics helps preserve the integrity of infrastructures and facilities that is mandatory for nuclear plants to last as long as possible.